Are you a lineman in search of protective, comfortable and quality work boots?

Management of your safety and protection is essential. This guide will help you find the perfect lineman work boots for your needs! You will find details on the features, materials and brands that make quality boots.

The utility industry is one of the most dangerous occupations in the world with the potential for fatalities and serious injuries. While safety education plays a role, lineman work boots have to be able to provide protection from job site dangers. The choice of footwear can make a huge difference in the ability to keep utility workers safe.

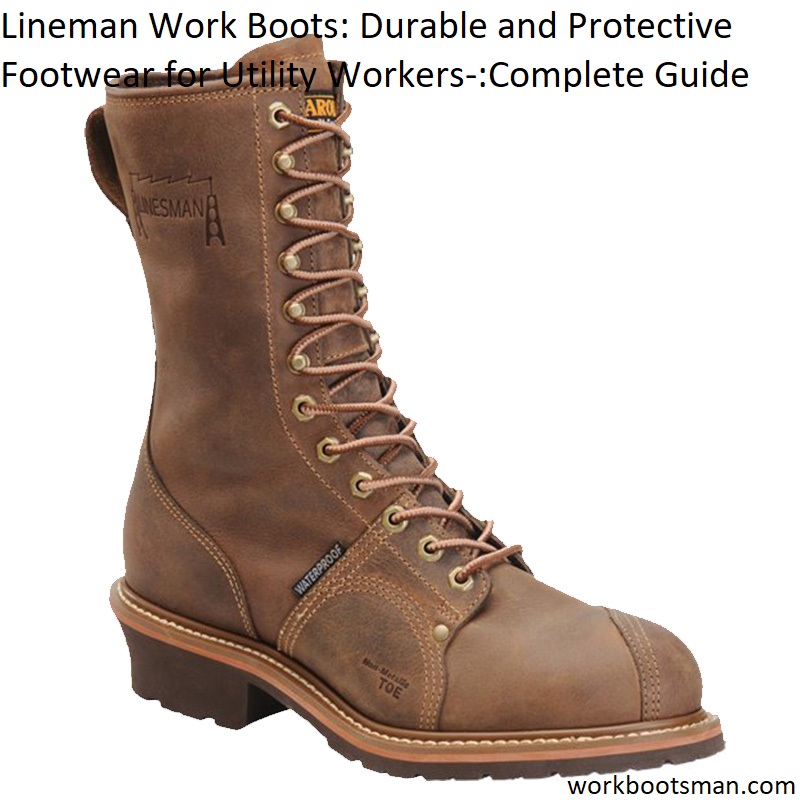

The demands placed on lineman work boots are difficult and specialized – not only must they remain comfortable for long hours but also be capable of protection from electric shocks, heat, cold temperatures and sharp objects. The following guide provides important information about these types of boots as well as an overview of some notable products available on the market today.

Safety features of lineman work boots

Today’s lineman work boots are designed with a variety of safety features that are essential for utility workers. Every lineman should find the right pair of boots to protect their feet on the job.

From steel toe protection to electrical hazard ratings, each safety feature plays an important role in helping utility workers stay safe on the job site. Here is a guide to understanding your options and choosing the best kind of lineman work boot for your needs:

Steel Toe Ratings – Steel toe boots provide maximum protection from sharp objects, falling debris, and other potential hazards that might occur while working. ASTM International has created a standardized rating system (I-75/C-75) for specifying steel toe strength and quality. The higher the rating, the greater the protection offered by each boot’s design.

Electrical Hazard Protection – Electrical hazard ratings reflect each boot’s ability to resist electrical shock in hazardous work environments. Commonly referred to as EH ratings, different scores denote levels of static dissipative performance tested in accordance with ASTM International standards (ASTM F2412-11 /F2413-11). The highest level is EH/75 which indicates that shoes should not permit electricity or voltage greater than 75 volts to pass through them.

Puncture Resistance – Puncture resistant outsoles prevent sharp objects such as splinters, nails, and staples from puncturing through your boots and injurying your feet on the job site. IEC 60529 outlines two types of puncture resistance testing procedures – Clay Method & Needle Method – designed to assess outsole’s ability in resisting spikes commonly encountered in industrial workplaces.

Slip Resistance – Slip resistant outsoles meet or exceed industry standards for workplace traction yielding better grip under challenging conditions such as slippery or wet surfaces. Running shoes often have enhanced slip resistance traits which you can find by looking at ASTM test results that measure coefficient of friction at various levels of wetness (0°C) including dry/oil condition & wet/oil condition (F2913-17). A higher number still makes it easier for you walk safely without worrying about falling over due to lack of traction on slippery surfaces encountered while working outside near power lines or other topography changes onsite..

Steel toe cap

A quality work boot for linemen must provide the utmost protection for feet on the jobsite. Impact, compression and puncture hazards are just a few of the dangers taking place in utility environments, so strong protective features are essential.

Steel toe cap boots are a go-to choice for linemen due to their strength and ability to provide protection against heavy objects being rolled over or dropped. Steel toe caps typically meet ASTM F2412-11 standards, making them ideal even in extreme conditions. Unlike some materials which can conduct electricity, steel toe caps have electromagnetic properties that make them suitable in electrical hazard work zones as well— though it’s still recommended to have non-metallic or grounded footwear nearby as an additional safety measure.

When shopping for steel toe cap boots, be sure to pay attention to the gauges used— usually 8mm or 12mm— and make sure that they meet industry standards required by your employer or specific job site.

Electrical hazard protection

Electrical hazard protection is of particular importance for utility workers, as electrocution and other electrical hazards are a major risk of the job. If a boot has an electric hazard rating, it means that it effectively reduces the shock from energized sources. These boots should have dielectric insulation and be able to pass specific tests and conform to ASTM standards to provide additional protection against live circuits, wiring, or other conductors in the work environment.

Electric hazard rated boots feature protective soles that are designed with special non-conductive shields. The uppers can be either rubber or leather, depending on your needs.

Slip-resistant sole

Slip-resistant soles are a must-have for linemen as accidents due to slips and falls are a common occurrence at job sites, especially when working on wet surfaces or in rainy conditions.

The slip-resistant outsoles of lineman work boots help prevent slips and falls while working, often providing better grip and footing than regular work boots. This is because they are designed with aggressive lugs or bumps on the sole, which dig into the surface of whatever you stand on, allowing you to stay stable and secure.

Some slip-resistant outsoles also have deep grooves which help expel water more efficiently when submerged underwater. Additionally, depending on the material used, some outsoles also provide better insulation against electrical shock.

For these reasons, it’s important to look for slip-resistant soles when choosing a pair of lineman work boots.

Comfort features of lineman work boots

When choosing lineman work boots, you want to take into account all of the essential comfort features that will make sure your feet remain comfortable and supported throughout the day. It’s important to remember that when you’re working long hours in hazardous conditions, the right pair of lineman work boots can be life-saving. Here are a few key features to look for when selecting your new work boots:

- Cushioning: Many lineman work boots are constructed with specially designed cushioning such as EVA and other foam-based materials that offer extra support and comfort with every step. This type of cushioning also helps reduce shock and fatigue while you’re wearing them on the job.

- Impact absorption: Look for boots with midsole cushioning and outsoles made with impact absorbing materials, such as rubber or polyurethane, which can help protect against shock and vibration associated with climbing high structures or pole walking.

- Insulation/waterproofing: Make sure your line worker boots have a waterproof rating of at least 7K so they will keep your feet dry when out in the elements – this will also help keep cold temperatures from severely impacting comfort levels while out in the field all day . Most lineworker footgear is also insulated against cold weather conditions, making it necessary to purchase those specifically calibrated for warmth if needed depending on where you work.

- Flexibility: A flexible boot helps promote natural movement and prevents injuries caused by overuse or restricted movements due to rigid soles. Many manufacturers engineer their lineworker shoes using lightweight materials such as fiberglass shanks or EVA midsoles to provide adequate flexibility without compromising support or protection.

Supportive insole

It is important that a lineman’s work boots feature a supportive insole. This will provide extra cushion and support while helping to prevent foot fatigue and injury.

Insoles can be made of variety of materials that range in terms of cushioning and support, such as air cushioning, memory foam and polymerized struts. A quality liner also helps keep the boots waterproof, which is essential for workers who are exposed to wet or damp conditions on the job.

Many insoles also feature antibacterial properties to reduce the risk of infection from sweat and dirt particles collecting inside the footwear. Additionally, it is important that the insoles can be removed for easy cleaning or replacement when necessary.

Cushioned midsole

The midsole is the core of the boot. It acts as a cushioning system that protects and supports your feet throughout the day, boosting comfort and performance.

It allows narrow shapes to fit a wide range of foot sizes, and also provides flexibility when you’re bending or climbing without sacrificing support for your foot. The midsole also helps absorb some of the shock generated by constant walking, kneeling, or standing on hard surfaces.

At the same time, impact protection contributes to a better grip since it helps reduce fatigue in the lower legs. Cushioning midsoles are lightweight yet robust for their intended use and can often be found in lineman boots with higher levels of overall protection.

Breathable materials

When shopping for lineman work boots, it is especially important to select a pair with breathable materials. Not only do breathable materials keep the feet cool and comfortable, but they also wick away moisture away from the feet, helping to prevent the growth of bacteria and fungus which can cause foot odors and infections.

Boots with leather uppers are often considered to be more durable than those made with non-breathable synthetic materials; however, some of these boots also offer breathable linings as well as breathable components like Gore-Tex membranes, which help to reduce humidity levels within the boot itself.

Beyond offering breathability, waterproof liners are another important feature of lineman’s footwear as these liners help to keep feet dry even when working in wet conditions.

Caring for lineman work boots

Taking proper care of your lineman work boots is essential to ensure their longevity and performance. Here are a few tips for caring for your boots:

- Cleaning – Regularly clean the exterior of your boots with warm water, a smooth cloth or soft brush, and an antibacterial soap. When finished, apply a quality boot dressing to help keep them supple. This can also help to prevent cracking and deterioration due to wear.

- Allow boots to dry naturally – Avoid using extreme sources of heat such as blow-dryers or placing them near strong air vents that can dry out the leather and/or damage the adhesive used in construction of your boots.

- Storing – When not in use, store your lineman work boots in an area with low humidity away from direct sunlight and extreme temperatures. This can help protect them against premature wear and tear.

- Polishing – Over time, the natural oils in leather can break down from exposure to dirt and salt resulting in less than ideal performance from the footwear — particularly if working at night when visibility may be important. Periodically applying wax polish/clear coat products will replace these natural oils helping keep your boots looking good as well as providing additional protection against wear/tear forces experienced in linemen environments.

Regular cleaning and maintenance

Regular cleaning and maintenance of lineman work boots is essential to ensure their durability and longevity. Unattended and neglected boots may begin to deteriorate quickly, leading to a decrease in performance. Cleaning your work boots is an easy routine you can follow that doesn’t require a lot of time or expense.

Before commencing any thorough cleaning process, always be sure to thoroughly remove dirt and debris from the surface of the footwear using a soft brush. This will help prevent any dirt particles from embedding deeper into the materials during the following steps. Afterward, you can apply a small amount of leather conditioning cream or wax polish on a clean rag and gently buff it into the leatherwork of your work boots in circular motions until it is fully absorbed. This process ensures that the leather material stays nourished and retains its durability over time.

Finally, check for damages or signs of wear and tear on your lineman work boots regularly (e.g., tears in stitching, separated soles) and immediately repair or replace them if needed to minimize any hazards that could occur while working with electricity or climbing poles outdoors. This will help make sure that these specialized utility boots provide maximum protection throughout their useful life!

Storage tips

The lifespan of lineman work boots depends on how well they are taken care of. To extend their life and durability, you should periodically inspect your boots for cracks, tears, or other damage. It’s also important to store them in a cool and dry space away from direct sunlight. Furthermore, if your boots come with laces, untie the laces and loosen them from the top eyelet each time you put them on before starting work. This will help prevent premature stretching and tearing of the laces.

It is recommended that once every two months you condition your lineman work boots with a reputable boot leather conditioner or cream for moisture protection as this helps increase their lifespan as well sheer comfort. Also remember to replenish the sole coating with waterproofing agents such as beeswax or shoe polish to keep them looking good while protecting their non-slip grip.

Repairing minor damage

Most linermen’s boots feature leather uppers to protect the foot from electrical shock. However, leather is susceptible to cuts and abrasions that can reduce its protective qualities. Therefore, it is important to check boots for signs of damage on a regular basis and repair any minor damage immediately with appropriate leather care products.

Make sure to dry and clean the surface thoroughly before applying any treatment, as moisture or dust can interfere with the effectiveness of the product. Leather conditioners are typically used to hydrate leather over time, so they can also be used to extend the life span of your work boots by preventing cracking or dryness that may occur in extreme weather conditions.

If you notice more serious damage, like deep scratches or holes, consult a professional boot repair service before attempting any fixes yourself.

Conclusion

When working with electrical utility installations, wearing the right shoes is vital for adequate protection against the risk of electric shock and ensuring that comfort levels are maintained throughout the job. Lineman work boots are specifically designed for linemen and ensure optimal protection against shock as well as increased durability and durability. From lightweight to heavy-duty constructions, there is a pair of boots suitable for all types of environment.

An effective combination of quality materials, sole technology and design make lineman boots a must-have accessory for workers in this industry. Prior to selecting any protective footwear, it is important to first understand the type of work environment you will be working in and check if there are regulations set in place by the company or official governing bodies regarding protective gear requirements. By investing in quality lineman work boots, you can be sure to have a steady footing while climbing utility poles, irrespective of weather conditions or duration of wear.

FAQs

What boots are best for a lineman?

Linemen need boots that are durable, slip-resistant, and provide ample support for their feet and ankles. Therefore, boots with a steel toe and a high-cut design are preferred.

What kind of shoes do linemen wear?

Linemen typically wear high-cut boots that offer support and protection to their feet and ankles. These boots should be slip-resistant and provide ample traction, especially when working on poles or climbing.

What boots do electrical lineman wear?

Electrical linemen wear boots that are specifically designed for their job. These boots typically have steel toes, high-cut designs, and are made of materials that are resistant to electrical hazards.

What is the use of lineman boots?

The primary use of lineman boots is to protect the feet and ankles of linemen while they work. These boots offer support and traction, making it easier for linemen to climb poles and work on electrical lines.

Do lineman need special boots?

Yes, linemen need special boots that are designed for their job. These boots provide the necessary support, protection, and traction that linemen need while working.

What should linemen wear?

Linemen should wear high-cut boots, gloves, hard hats, and other personal protective equipment (PPE) as required by their employer. They should also wear clothing that is appropriate for the weather conditions and job site.

What brand makes the best linemen shoes?

There are several brands that make high-quality lineman shoes, including Red Wing, Danner, Timberland PRO, and Carolina.

What boot brand is best for work?

The best boot brand for work depends on the job and the specific needs of the worker. However, some of the most popular and trusted boot brands for work include Red Wing, Timberland PRO, Wolverine, and Georgia Boot.

What is a good size for a lineman?

The size of lineman boots depends on the individual’s foot size and shape. It is essential to get the right size to ensure maximum comfort, support, and protection.

What accessories should lineman wear?

In addition to boots, linemen should wear gloves, hard hats, eye protection, and any other PPE required by their employer. They may also benefit from wearing safety harnesses, tool belts, and other equipment specific to their job.

See Also:

- Best work boots for overpronation 2023

- Best work boots for sweaty feet 2023

- Best wellington work boots 2023

- Best women’s boots for farm work 2023

- Best women’s pull on work boots 2023